Downlite Outdoor, a market leader in responsibly sourced down and fills, highlights its newest technology with traceable down-trac. Live demonstrations are being conducted today and tomorrow during the Functional Fabric Fair at the Oregon Convention Center in Portland.

Here’s how down-trac works: Each lot of down and feather that Downlite produces receives a unique identifier at each stage of the process, which is combined into a final lot number when the material is readied per a brand’s requirements.

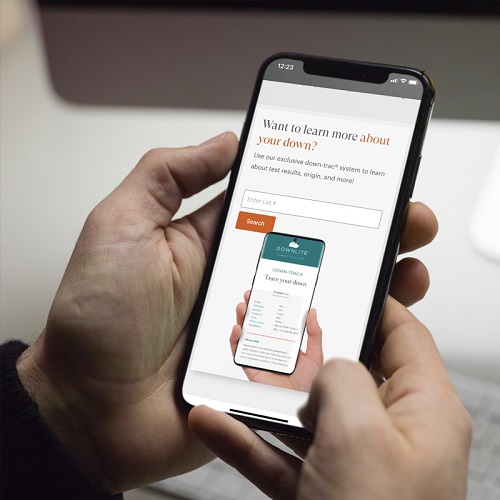

Retailers can integrate the system on their own websites, allowing consumers to either enter the lot number into a search bar or scan a tagged QR code to learn details about a product’s natural fill, from fill power to its origin. The system is free and all information is consolidated based on third- party traceability audits and testing.

To hear more about the down-trac process, listen to this podcast interview with Downlite President Josh Werthaiser on Rick Seaz Outdoor Biz (Episode 321, posted March 22, 2022).

Downlite originally was engaged by The North Face and Textile Exchange to help collaborate on the development of the Responsible Down Standard (RDS). Downlite was the first RDS Scope Certified down supplier, and the brand is an active stakeholder in the RDS revision process.

In 2012, with the collaboration of Patagonia, Downlite developed the Traceable Down Standard (TDS). Downlite was offered the first TDS-certified supply chain in the world, from both Europe and the United States, and is a member of the American Down & Feather Council (ADFC), and four additional classifications.

For information, visit Downlite Outdoor