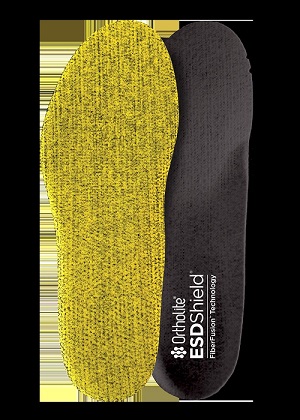

OrthoLite, an industry leader of branded, high-performance and comfort footwear solutions, has introduced OrthoLite ESD Shield, a mechanically bonded electrostatic discharge protection insole technology. OrthoLite ESD Shield is available in molded insoles and delivers heel-to-toe ESD protection.

Ideal for work and service footwear, ESD Shield is a top cover system that uses OrthoLite’s patented Fiber-Fusion technology using conductive copper fibers that require no-glue and is mechanically bonded to OrthoLite X35 foam designed to deliver ESD insole protection that doesn’t degrade while providing the comfort and performance.

Unlike conventional ESD insole technology that depends on a single row of stitching under the toes, ESD Shield elevates electrostatic discharge effectiveness through an innovative, patent-pending process that mechanically bonds the conductive fibers permanently from heel to toe into the OrthoLite foam using thousands of elliptical needles.

OrthoLite worked with third-party testing laboratory Intertek to quantify ESD Shield’s performance. Intertek testing results validate that ESD Shield measures in at less than 0.01 milliohm (mΩ), which is a 1,000 times difference in ESD performance based on the ISO Standard 20344 – 2011 – the industry standard for ESD footwear requiring electrical resistance of less than 100 mΩ.

Additional third-party testing was conducted for wear, abrasion resistance, die migration and peel strength. Testing protocol and results can be reviewed here.

As a vertically integrated U.S. company with facilities around the world, OrthoLite collaborates with its brand partners to create and produce custom insole formulations that deliver unrivaled comfort and performance.

For more information on the new OrthoLite ESD Shield insole technology, visit ortholite.com.