TMC Ltd, the owner of Nuyarn spinning technology, unveiled Herculan, a product that offers improved performance benefits of wool coupled with the durability and sustainability for the apparel sector.

A result of more than three years of R&D, Herculan is a patented technology that was developed by making ground-up modifications to TMC’s proprietary Nuyarn spinning machines, enabling them to accommodate strong wool – the coarsest and most durable grade of wool fibers (>38 microns) historically suitable only for interior textiles, like flooring and upholstery.

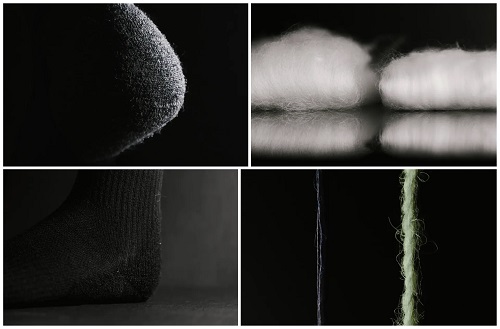

This “carpet wool” as the industry coins it, has a low market value and during recent bearish years was often cost-prohibitive to process, package and ship. Therefore, it was discarded into landfills. According to the International Wool Textile Organisation (IWTO) it is estimated that anywhere from 40-50 percent of the global wool yield is interior textile wool. With the innovative technology, these coarse long wool fibers are drafted around a performance filament, creating a fine yarn – Herculan – which outlasted some of the industry’s leading synthetic textiles in the Martindale abrasion tests.

Because of its durability and performance, Herculan is an emerging technology that opens the door for wool to be used in high abrasion and high impact zones in apparel such as socks, footwear, gloves, pants, outerwear and thousands of other potential applications, without succumbing to wear.

In addition to its durability, Herculan has better performance and comfort benefits to natural wool textiles (that is twisted) and synthetic fibers; efficient moisture management and quicker dry times, higher volume, aeration, elasticity, and thermal retention, non-reflective, quiet, and naturally odor-resistant.

Herculan’s yarn construction is built by drafting carpet wool around a performance filament without twisting or fraying.

Sustainable manufacturing processes like Herculan, which take advantage of materials that often are cast aside, simplify supply chains and encourage end-users to waste less by making natural fiber garments that last longer and have performance comfort benefits.