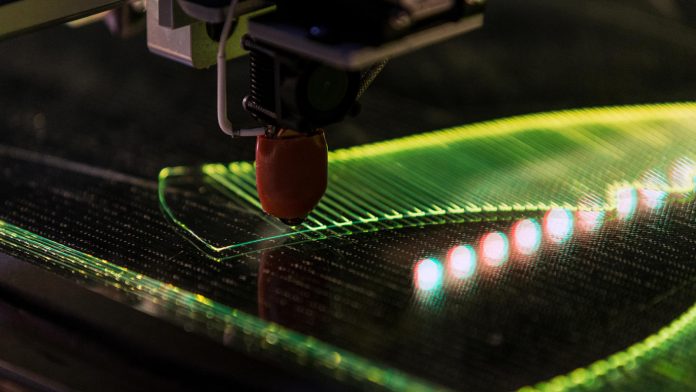

Nike’s new Flyprint is the company’s first 3D-printed textile upper within its performance footwear. At its most basic level, Nike Flyprint uppers are produced through solid deposit modeling (SDM), a process whereby a TPU filament is unwound from a coil, melted and laid down in layers.

According to the Nike, the Flyprint method allows designers to translate athlete data into new textile geometries and digitally enabled textile development.

The process to develop the Flyprint uppers begins by capturing athlete data. That data is then computed (through computational design tools) to affirm the ideal composition of the material. Finally, that information is employed to produce the final textile, says Nike.

“This operation speaks to the versatility (outputs can be wholly unique to athlete or function) of Flyprint textile, as well as the increased pace of overall design time,” said Nike in a new post. “Through performance printing, Nike is capable of moving faster with unprecedented precision — prototyping is 16-times quicker than in any previous manufacturing method.”

“One interesting benefit of 3D textiles over traditional 2D fabrics is the increased dynamism made possible by adding an interconnection beyond a warp and weft; an advantage of Flyprint textiles comes in the fused nature of the material. For example, whereas in a knit or woven textile there is frictional resistance between the interlaced (warp and weft) yarns, in a printed textile, due to its fused intersections, there is greater potential for precision-tuned containment. It is also lighter and more breathable than Nike’s previously employed textiles,” continued the company.

Nike says the advantage of Flyprint method in traditional textiles is two-fold: specific lines of the material can be adjusted locally while preserving the global construction, and rapid iteration means testing and revision cycle times are trimmed significantly. In short, Flyprint allows for the highest-fidelity design with the greatest athlete benefit in the shortest time.

The textile also works seamlessly with many other materials, most notably Flyknit yarns, to provide an optimal balance of fit and structure. In fact, Flyknit yarns can be engineered to thermally bond with the Flyprint textile, eliminating any need for glue or stitching.