Direct

Feed

www.insideoutdoor.comFloorSpace

Direct

Feed

www.insideoutdoor.comFloorSpace

Outdoor

Textile

Green

Glossary

Retail

Report

Outdoor

Textile

Green

Glossary

Retail

Report

www.insideoutdoor.comProducts

Section

www.insideoutdoor.comProducts

Section

Inside

Outdoo

r | Winter 2016 65that larger pay rate, and that reliable,

safe job every time.”

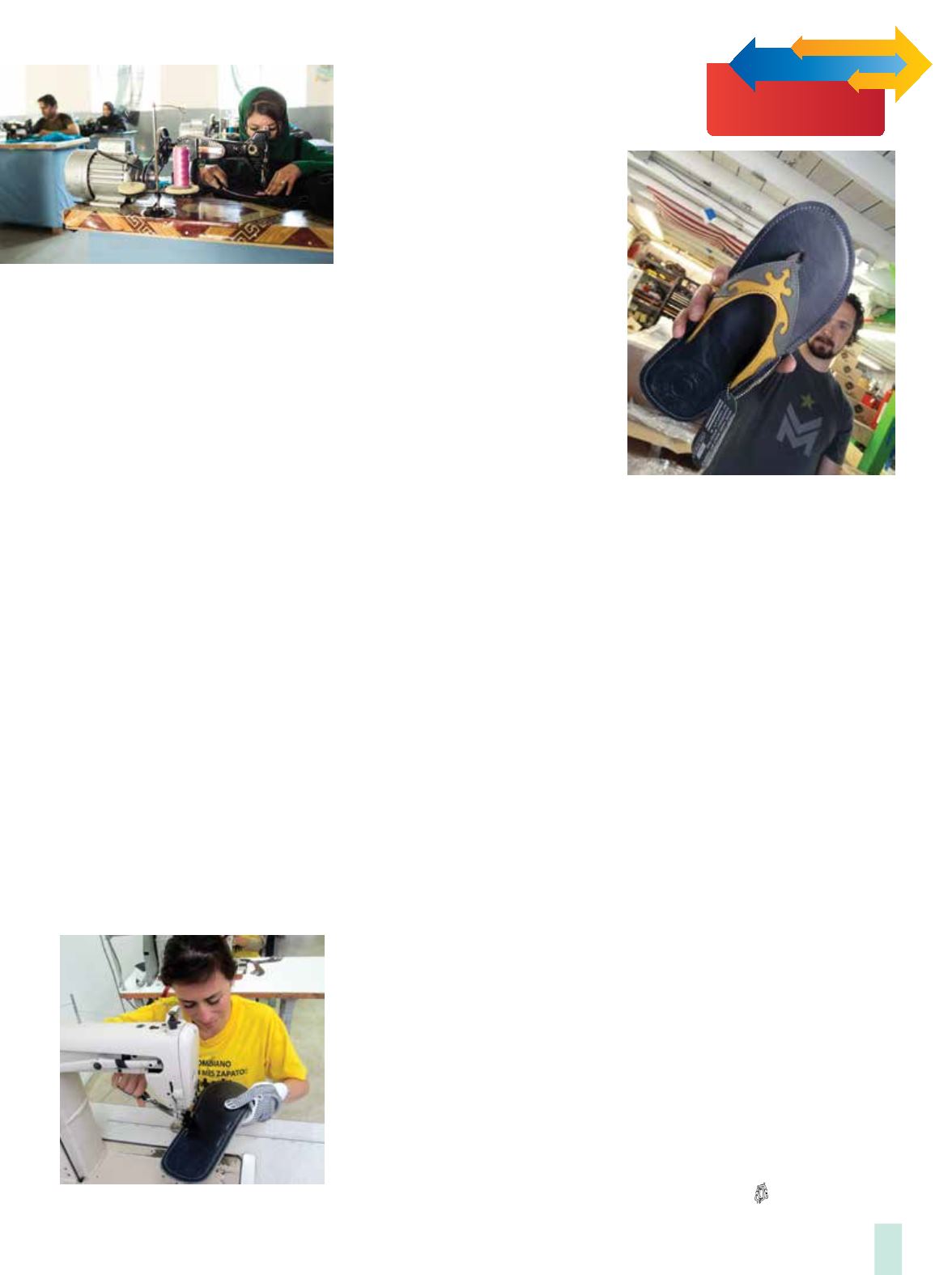

Due to some logistical and geopoliti-

cal challenges, sandal production in Af-

ghanistan had to be suspended, but the

company re-deployed its efforts in Co-

lumbia, a country torn apart by years of

narco-financed counter-insurgency wars.

Near Bogota, the company partnered

with a local manufacturer known for

high-end leather footwear. Today, they

operate a facility that runs at capacity

producing Combat Flip Flops’ gr wing

collection of sandals. The raw materi-

als, from cow to finished product, are

sourced within five miles of the factory.

Not that Combat Flip Flops has

given up on Afghanistan. Having served

multiple tours of duty in the country,

and witnessing firsthand the persis-

tence and creativity of its people, both

Griff and Lee harbor deep and personal

connections to its future prosperity. So

with the help of a local aid organiza-

tion, CFF found a women-owned factory

in Kabul that was making curtains and

uniforms for the growing hotel market

and

service industry. Hand-made sa-

rongs and shemaghs scarves are now

sewn and embroidered at this factory

for CFF, and the purchase of each one

places an Afghan girl in secondary

school for up to a month. In 2015,

the program amounted to 59 years of

schooling for Afghan women and girls.

Keep in mind, Afghanistan is a

country where the literacy rate among

women is about 15 percent. “Think of

how easy it is to radicalize a child with

no education because his mother had

no idea of the value of an education,’”

said Griff at a recent TEDx Talk on

manufacturing peace through trade.

Indeed, 30-plus years of war and

tribal conflicts has led to a massive

population of widowed women who lack

the skills to provide for themselves.

Another former soldier turned philan-

thropist runs a program in Jalalabad

training Afghan widows to read and sew.

During a four month course, Afghan

widows are taught fundamental literacy,

math, hygiene and sewing. At the end of

the course, the women are given a non-

powered, home sewing machine and

the basic skills to earn a living. Since

thes women don’t have power, lots of

materials on hand, and only basic sew-

ing skills, Combat Flip Flops designed a

simple product that could be made just

about anywhere. That’s the story behind

CFF’s Harvest Belt.

Then there’s the Peacemaker brace-

let made in Laos. Rural residents of

this Southeast Asian country still suffer

the effects of some 270 million bombs

that were dropped by the U.S. military

during the Vietnam War. That’s the

equivalent of a B-52 load of aluminum-

laden explosives falling out of an air-

plane every 8 minutes for 9 years, said

Griff. More than 85 million of those

mines still lie in the earth unexploded.

In order to farm the land, graze ani-

mals or simply to collect the scrap met-

al to melt down into everyday utensils,

locals detonate these bombs, typically

without proper protocol and safety

measures. As might be expected, these

unregulated detonations often lead to

accidental deaths.

“I have seen what happens when a

kid picks up a live round,” said Griff.

To help combat this problem, CFF

is working with local artisans in Laos

to make bracelets from the scraps of

bombs and mines detonated properly.

CFF then donates money from each

Peacemaker bracelet sold to safely clear

three square meters of unexploded or-

dinance in the region. In 2015, nearly

2,000 square meters of landmines were

safely removed through the program.

Continuing around the world, CFF

also is working with a fashion incubator

in Seattle that trains vets to sew and

places them in jobs. The Chest Rig neck-

tie from CFF, made from hemp and re-

cycled PET, is a product of this program.

Over in Eu

rope, CFF also can be foundin Kosovo, a country torn apart by war

in the late 1990s that today faces a

poverty rate upward of 29 percent and

an unemployment rate of more than 35

percent. Here Griff and company work

with a local embroidery shop to do their

embroidering and make patches for

their accessory collection.

As one can see, it’s a lot to convey,

and Combat Flip Flops has come up

with several clever catch phrases in at-

tempts to crystalize its mission: “Manu-

facturing Peace through Trade,” “Bad

for Running. Worse for Fighting,” “We

make cool stuff in dangerous places,”

“Welcome to the Unarmed Forces,”

“Business, Not Bullets” and “Manufac-

turing Stoke,” among them.

But now through a new POS dis-

play, outdoor stores can dedicate a

small piece of floor space to help CFF

spread the stoke. We are confident it

is a story that will resonate with out-

door consumers.

A worker at the facility in Bogota

Griff showing CFF’s Poseidon sandal

An Afghan women works on a CFF

sarong at the factory in Kabul