the understanding that all societies,

including traditional communities,

exist in a state of constant flux. We

are always changing; nothing is static.

This runs counter to the (Western)

view that traditional societies should

be preserved as they always have

been. Kora’s view is that nomad

culture and nomad societies are also

changing and adapting to the new

world around them – to survive, they

must. We would like to help them

adapt in a way that protects their

cultural heritage and identity. For

kora, this is about empowerment

and education.”

Indeed, and within that scenario

is the world’s reliance upon ancient

stewardship practices nomadic com-

munities still provide to the grasslands

of the Tibetan Plateau. Not just only

for themselves but for the billions of

inhabitants downstream and ultimately

around the world.

Clearly, expending so much energy

to bring logistically challenged yak to

market implies it must be pretty spe-

cial. It is.

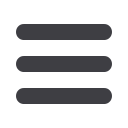

First, it is a very fine fiber but

strong even at 18.3 μm, as used

in kora’s Hima-Layer Original 230

yarns. The fibers are claimed to be

hollow, fire resistant, anti-microbial

and hydrophobic. Kleinwort reports

testing done by SGS shows yak is

40 percent warmer than merino,

weight-for-weight. He also shows

results from a Sheffield Hallam Uni-

versity’s Centre for Sport & Exercise

study concluding yak maintains

homeostasis better than polyester

or merino wool base layers (see

table). The kora website also main-

tains kora’s yak “is 66 percent more

breathable and is 17 percent better

at transporting water vapour away

from the skin.” Anecdotal feedback

from athletes-testers confirms

those assertions when comparing

similar merino.

When all the testing is eventually

finished, there is no doubt, yak will

be among the elite natural fibers, and

kora will take its place among the elite

brands. And in no small way, kora’s

efforts to achieve the trifecta in sus-

tainable development will unquestion-

ably help them get there.

United Under Bison

United by Blue’s founder Brian

Linton is obsessed by water. So

much so, in 2010, he started UBB

and with it a “pledge to remove 1

pound of trash from a river or ocean

for every product UBB sells.” Ac-

cording to UBB’s website, as of this

writing, 312,402 pounds of trash have

been picked up between 155 clean-

up events. Additionally, UBB has

committed to the B-Corp framework

and has been certified since 2011 (its

score is double the median grade).

Then there is the product line, with

each item curated to fit into UBB’s

ideal of doing right while doing good

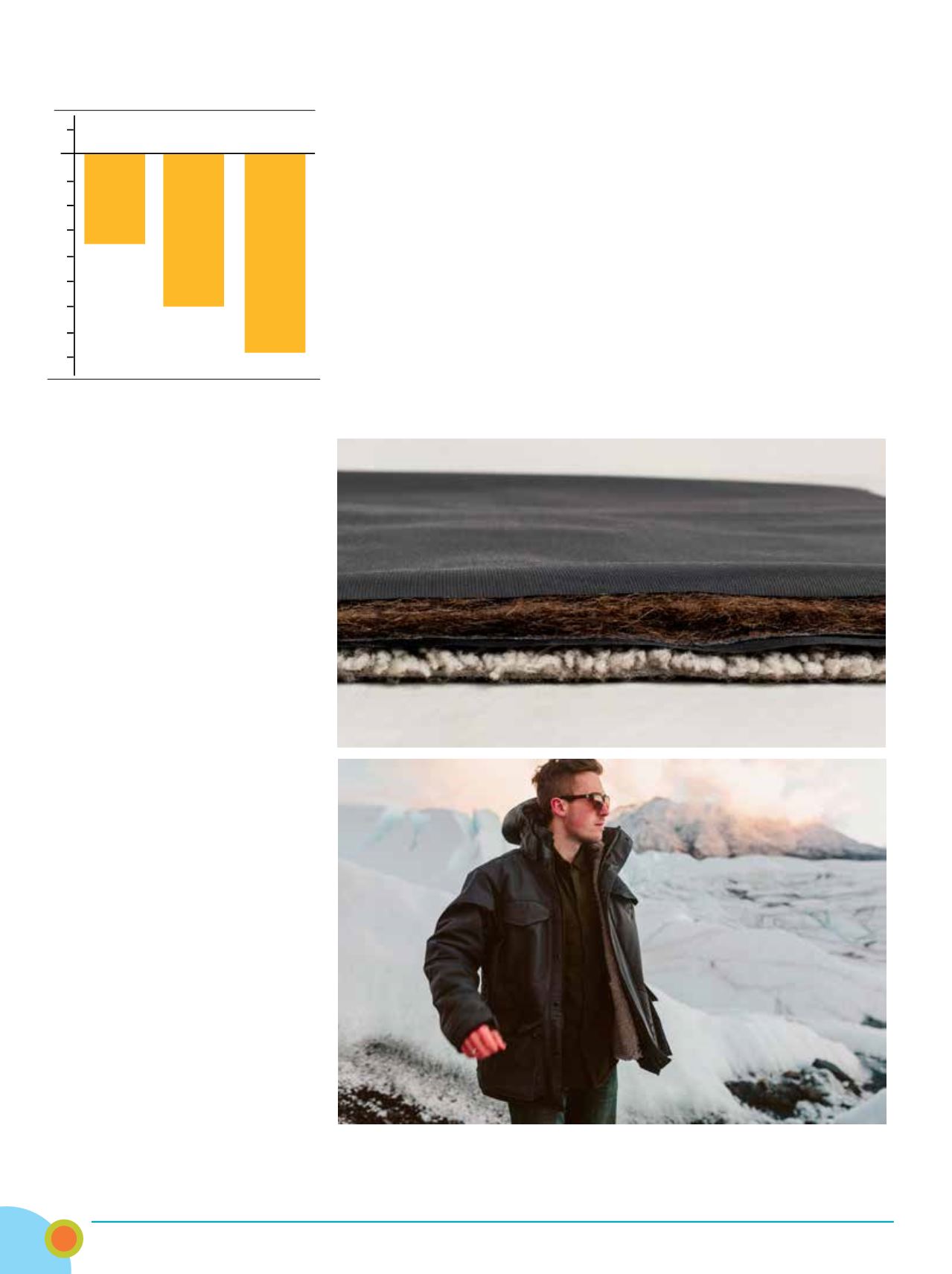

(Top) Cross section of United By Blue’s B100 bison insulation. The hollow bison fibers

used in this 60% bison/40% recycled polyester non-woven insulation increase the

overall thermal efficiency of the batting, giving it a third party tested 4.5 CLO value.

(Bottom) The Ultimate American Jacket, insulated with B100 insulation. MRSP: $598

Thermal Loss During 1 Hour

Running in - 5C

Source: Sheffield Hallam University’s Centre for Sport & Exercise Science; kora

SHOLA

BASE LAYER

1

0

4

-2

-3

--4

-5

-6

-7

-8

MERINO

BASE LAYER

POLYESTER

BASE LAYER

Mean Relative Temperature Changes (C)

(Continued on page 82)

Inside

Outdoor

|

Summer

2016

32