The SuperWash

debate is centered on

the chemical waste in

the process, the wa-

ter consumed and the

long-term public health

risk to low levels of

carcinogens. Ironically,

these same chemicals

essentially catapulted

the staid wool industry

into the 20th Century.

Unfortunately, as seen

time and time again with

technological advance-

ments, a leap in technol-

ogy xsometimes brings

unforeseen consequences. Although

there have been successful efforts to

address the chemical conundrum, the

majority of SuperWash is still done in

the same, not eco-friendly way, in third

world countries.

‘A’ is for Alpaca

Shawn Malloy, co-founder of Altera,

is not just a marketer. From farm to fi-

ber, Malloy knows all things alpaca and

then some. His company, Royalty Fiber

Farm and sister company U.S. Natural

Fibers, specializes in handling bou-

tique protein fibers such as alpaca, yak

and bison. For Altera, Malloy only uses

a small network of U.S. farmers con-

sidered to be in the premium alpaca

fibers space. Using these exceptional

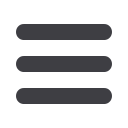

The Dirt on SuperWash

Brand Fiber

Source

Fiber

Diameter

microns

Fiber

monolithic

or hollow

Super

Wash

Hydrophobic Anti-

bacterial

Fire

resistant

Other properties

Altera Alpaca 16-30+

Altera socks:

23-24 μm

Hollow

No

Yes

Yes

Class I fiber

by FTC/CPS

Hi loft, pills less

than wool, ½ the

moisture regain as

wool 8 v 16%

Kora Yak

18.3μm

18-20

17-25

Hollow

No

Yes

Yes

Yes

Wicking, SPF 40,

low lanolin, lower

moisture retention

than sheep, stronger

than sheep wool

United

By Blue

Bison

6-7 μm Mono

guard hair

hollow

No

Yes

Yes

n/a

Stronger tensile

strength than

merino, wicking,

high moisture

retention

Source: Bison Wool Properties; International Textiles & Apparel Association; Company reports

S

uperWash, as thought of by some

consumers, is not just pre-washed wool.

It is a process to make wool consumer

machine washable by minimizing its propensity

to shrink. A byproduct of this chemical process

is to impart better resistance to pilling and

abrasion, plus making the finished product

softer and less scratchy.

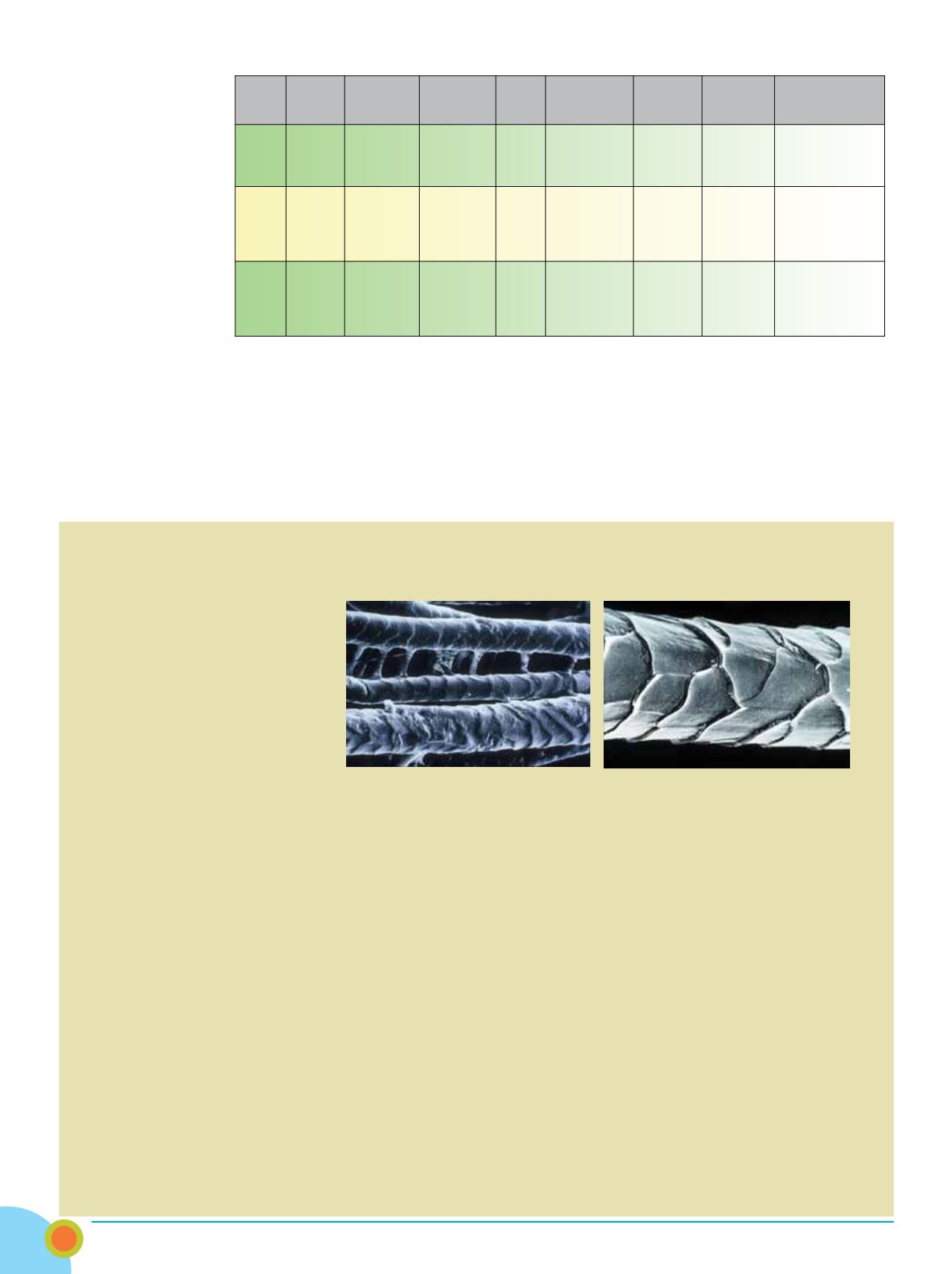

The method commonly used to do this

is the very effective Chlorine-Hercosett-

Process. At its most basic, it is a two-step

process: 1) it prepares the fiber surface for 2)

a follow-up plastic resin coating. The procedure

both reduces and covers the scales seen in

Figure 1, which without treatment, cause the adjoining fibers

to continuously interlock, ratcheting themselves ever closer

(shrinking). ZQ Merino likens the SuperWash process to hair

conditioner: it makes hair smooth and tangle-free.

As effective as it is, SuperWash does not come without serious

environmental considerations. This process requires energy, water

and has elements to it that are environmentally damaging. A 2009

European Commission study conducted by its Directorate-General

for Environment’s LIFE Programme disclosed that for 1,200

tons per annum of SuperWash wool produced, it required “150

tons of sodium hyphochlorite (household bleach), 220 tons of

polyaminoamide resin and 165 tons of other compounds such as

sulfuric (car battery) acid, wetting agents and defoamers.” These

“environmentally hazardous substances,” in combination with the

large quantities of water, form wastewater laden with significant

levels of Adsorbable Organic Halogen compounds or AOX. The

investigators found, “The AOX-loading can be up to 40 milligrams

per liter (40 ppm) and mainly due to the chlorination step, but

also from the resin treatment.”

Consequently, short of adequate water purification at the end

of the factory’s effluent pipe, water contamination by chlorine by-

products is guaranteed. In water treatment circles, many of these

contaminants are known as disinfection by-products (DBP).

DBPs created by chlorine during the SuperWash cycle have

been studied extensively but for another reason. A paper published

in 1974 by Technical University (Delft, Netherlands) researcher J.J.

Rook established a link between DBPs and sodium hypochlorite

used as a disinfectant in municipal drinking water. Rook observed

when a specific compound from sodium hypochlorite was

combined with water and organic matter occurring naturally, it

morphed into four primary THMs (trihalomethanes). As it turns out,

the compound is hypochlorous acid, the same hypochlorous acid

that revolutionized the wool industry via SuperWash.

The LIFE Programme’s final report concluded SuperWash

results could be practically achieved through other technologies

without the chemicals that form DBPs and with virtually no

water and a small increase in energy use offset by the cleaner

technology. However, as this article will show, some of the fibers

are so smooth, SuperWash is not necessary.

(Left) SEM (scanning electron microscopy) view of polymer coated wool

fiber. Note scales on the merino fiber’s surface (Right). SuperWash effectively

reduces the scale’s profile and the resin smoothes them over adding softness

and abrasion resistance. Source: CSIRO, Canberra, Australia

Inside

Outdoor

|

Summer

2016

28