engineer in both government and in-

dustry, were looking for a spot remov-

er for organic-based fabric, relates

Fitz Lee, president of Tredagain.

“At one point they kept thinking

they had defective rubber stoppers,”

says Lee, “until they realized this was

pretty special, and they spent the

following few years isolating the phe-

nomenon and optimizing the process.”

Their proprietary Fan Process,

named in honor of the late Dr. Fan,

uses rubber crumb from tires to

devulcanize into APX, a 100 percent

virgin rubber or virgin rubber substi-

tute. A patent application was applied

for in 2006 and later issued.

In 2007, Fan, Shafie, Lee and a few

other colleagues went on to form Green

Source Holding Company, a business

dedicated around “opportunities that

use technology to solve resource effi-

ciency issues.” Austin Rubber Company

and Austin Footwear Labs are two of

the core businesses. Fan and Shafie’s

breakthrough technology is what pow-

ers Austin Rubber Company’s bread-

and-butter product APX.

APX, in turn, is used by Austin

Footwear Labs’ Tredagain footwear,

Green Source Holding’s demonstration

platform for APX. Which is why Austin

Footwear Labs’ Tredagain is so special:

it is the first use of APX in what is to be

a revolution in the upcycling of waste

rubber to high-performance second,

third or potentially innumerable prod-

uct reincarnations. The other plus side

of APX is its affordability. It is cheaper

than virgin rubber with no performance

downsides, says the company.

“The best part about our story is

that consumers can’t tell we are us-

ing APX since quality, durability and

performance are not compromised,”

says Lee. “Our goal with Tredagain

was making fashion, sustainability and

affordability come together.”

Lee is quick to emphasize that this

product is not recycled. It is upcycled.

“No longer is a token 1 to 3 percent

of factory scraps as filler (i.e. non-

functional component in the rubber

master batch) going to cut it with the

educated consumer. Upcycle not re-

cycle is the new industry

standard, and 50 per-

cent is the new sustain-

ability goal,” says Lee.

On the quality and

durability side of the

equation, Lee’s numbers

on APX seem to bear

things out. For those

familiar with Shore hard-

ness nomenclature, an

outsole rubber sample

and one with 50 percent

APX have about the

same value (see table).

What’s the maximum amount of

APX used in a given master batch?

“Depending upon the specific physi-

cal and dynamic qualities you are tar-

geting, there are upper limits for each

compound,” Lee explains. “Since APX

comes from tires, there will be some

physical properties it will not provide on

its own, so different virgin materials will

need to be added to achieve them.”

Tredagain sandals carry 50 per-

cent loads of APX (with load being

the weight percentage of total rub-

ber compound), “but Austin Rubber

has hit 80 percent loads on other

compounds that do not require the

same dynamic properties,” contin-

ues Lee. “We have in-house polymer

compounding capabilities to help our

customers to select the correct com-

pound for their application.”

For now, Tredagain is focused on

men’s and women’s sandals, but Lee

promises new urban rain boots for

Fall 2016. Consumers who purchase

online will be glad to see Tredagain

ships using recycled packaging,

stamped not printed shipping labels

and recyclable shape-holding inserts.

It’s all part of that better footprint.

Specs/

Targets

0% APX 25% APX 50% APX Test Method

Durometer

60-65 Shore A 62-64 Shore A 63-64 Shore A 60-62 Shore A ASTM D2240

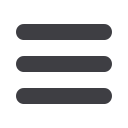

Tredagain’s hand-stitched Woman’s Classic Sandal (sand)

Comparison between Austin Rubber APX at 25% and 50% concentrations versus

typical rubber used for footwear outsole applications (Courtesy of Fitz Lee, Tredagain)

Inside

Outdoor

|

Spring 2016

19