backed on the supercritical CO2 are

more uniformly deposited throughout

the swollen microscopic nooks and

crannies that make up polyester.

When the CO2 is removed, the poly-

ester returns to its original shape,

locking the pigments in. The end re-

sult is a very consistent, permanent

color in contrast to water-based dye

baths that require heat, pressure and

time to force good color saturation

throughout the polyester.

How waterless is Drydye? As

noted above, the actual dyeing can

take place at various points along the

dyeing process. Drydye begins its

intervention after the pre-treatment

process seen within the red box in Fig-

ure 1. From that point forward, the dye

process is waterless. That is because

supercritical carbon dioxide is used

instead of water to carry the dye. Yet

the advantages do not stop there.

The supercritical process is con-

ducted in a closed environment, so 95

percent of the CO2 is captured to be

used again in the next batch. Since

the dyes do not require additional

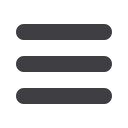

Figure 3. Post-dyed polyester pellets before converted to a solution that is drawn

into fiber. Since the color is already in the pellets and therefore in the solution, the

dye process is essentially over before the fiber is spun into yarn.

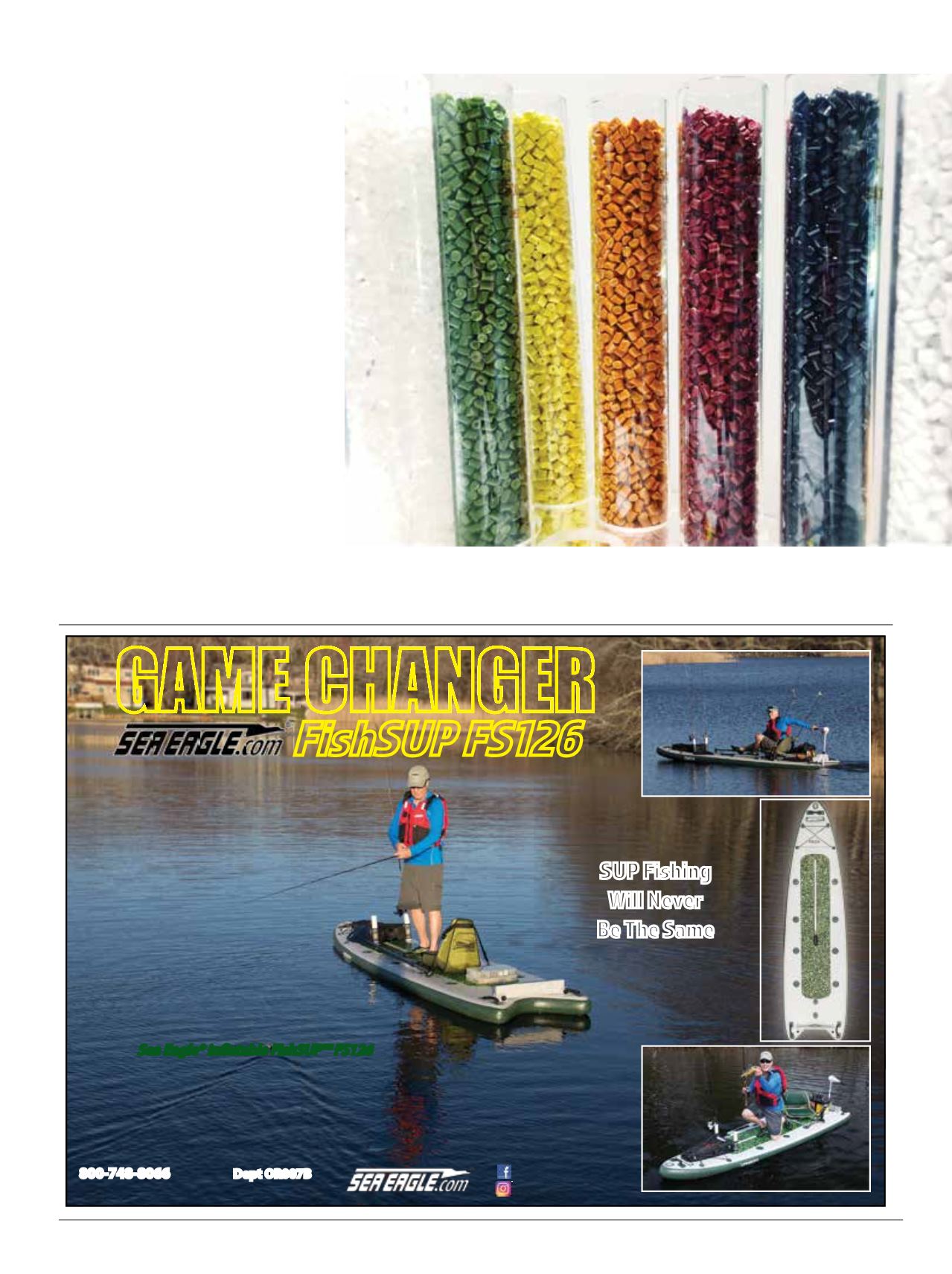

The new

Sea Eagle® in atable FishSUP™ FS126

was designed speci cally for anglers.

A full 12’6” x 40” for incredible stability, EVA foam pad for secure stand up footing

when needed, heavy duty two layer drop stitch construction for a solid, super tough

SUP board and multiple d-rings and elastic cord for gear. Motor mount holds up to

a 55 lb. thrust electric motor. Paddle standing up or sitting on the Sea Eagle® Swivel

Seat Fishing Rig.

Packages start at $899

(NY &WA residents add sales tax).

GAME CHANGER

FishSUP FS126

800-748-8066

M-F 9-5 EST

Dept OR007B

19 N. Columbia St., Suite 1, Port Jefferson, NY 11777

/SeaEagleBoats

/SeaEagleBoats

SUP Fishing

Will Never

Be The Same

SUMMER

2017

|

Inside

Outdoor

37