Fortunately, new technologies continue to

arrive, presenting compelling cases to ditch the

entrenched paradigms of today’s dye industry.

To fully appreciate how much better these new

technologies are, an understanding of what con-

stitutes the hot mess of today’s current technol-

ogy requires a short primer.

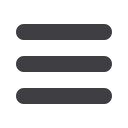

Getting color into our mountain parkas, school

daypacks and Burning Man tents is achieved

through several commonly used processes. Be-

cause of the variables encountered with different

finishes and fibers, the actual dyeing treatment

can start at various points up to the finished

product. For example, filaments can be spun into

yarn, then the yarn dyed by the package, a kind

of king-sized spool. Globally, the most common

method has undyed yarn woven or knitted into

fabric, then dyed (piece dyeing). Figure 1 shows

a generic flowchart of the processes involved in

the manufacturing of textiles.

Water figures prominently throughout the

entire process, yet within that process, the dye

step consumes a large share of it. Although

cotton by far uses the most water in becom-

ing a finished product, the focus here is on the

outdoor industry’s reliance on polyester, not to

mention the vastly larger world market.

Figure 1. A generic look of the dye process involving knitted or woven textiles. Nearly every step of

the way involves the use of water (Water and Chemical use in the Textile Dyeing and Finishing Industry,

The Environmental Technology Best Practice Programme). The red box represents the pre-treatment

of the yarns or fabrics before dyeing.

Figure 2. The critical point were carbon dioxide (CO2) becomes supercritical

is at 88F/31C and 1,071 pounds per square inch/7.39 MPa (Image: Creative

Commons CCO 1.0 Ben Finney, Mark Jacobs, 2010)

50%

60%

48.1%

42.9%

Inputs

Hot water

Detergent

Alkali

Water

Pre-Dye Treatment

Bleaching agent

Water

Dyes

Water

Inks

Water wash

Heat

Resin

Retardants

Process

Desize

Scour

Bleach

Dye

Finish

Waste

Hot water

Dilute detergent

Dissolved size

Dilute spent chemical

Hot water

Trace contaminants

Bleach

Water

Unfixed dye

Water

Unfixed inks

Water

Unfixed chemicals

Waste heat

Liquid

Gas

Solid

Supercritical

Fluid

Critical point

1

10

200

250

300 350 400

100

1,000

10,000

pressure

P (bar)

temperature

T (K)Triple point

Inside

Outdoor

|

SUMMER

2017

34