Depending on the technology readiness

level, we can refer them to Natick, Army

Research Laboratory, Navy Laboratory,

or other REDECs. People approach PEO

Solider all the time with ideas.

IO:

So it’s okay for companies to

come to you with ideas, and you can

send them in the right direction?

DR. ZHENG:

I want to em-

phasize that we have many prob-

lems and challenges. We are com-

mitted to the soldier and have a

very long list of technologies that

we need to develop. One of the

challenges for individual clothing

is combining those functionalities

into one fabric.

IO:

Dr. Zheng, with regard to

doing business with the govern-

ment now, is sequestration an

issue? Has funding gone down?

Is it going up?

DR. ZHENG:

With the military,

specifically for protective items,

it’s never an issue. Programs for

protective items are always very

strongly supported. Protecting

soldier’s lives and making equip-

ment more effective is the number

one priority in the Army. If there

is an unfulfilled need, it’s not due

to lack of money, it’s that we don’t

have the technology available to

meet the need.

IO:

So if a company devel-

oped a phenomenal technology

that solved several problems for

you, and the Army said we want

this, then the Army would move

toward making sure there is funding

for that?

DR. ZHENG:

We would first have

to perform an evaluation to make sure

the new technology actually improves

performance. Another factor that can

affect how we develop and field items

is military conflicts. In the past, we

have developed a new item with the

plan to procure it very slowly over

15 years. Then we went to

war and needed to purchase

everything in two or three

years. If we have to send

our soldiers in harm’s way

to protect the U.S. and our interests,

we have to give our soldiers the best

materials and equipment.

IO:

That’s a tall order when you

factor in all of the properties you need

in these products. So part of your job is

readiness?

DR. ZHENG:

Right. With regard to

R&D, we never stop and we are always

looking ahead. Every month, every year

there is constant research and plan-

ning. We are constantly preparing for

the worst thing to happen. My job is to

make sure we have those technologies.

We have to be ready.

IO:

So you are always looking ahead.

DR. ZHENG:

Yes. Ultimately we are

looking ahead to 20, 30, even 50 years.

Some developments may be three or five

years away. In the short termwe perform

technical assessments and determine

which technologies can be developed

quickly. The Army is constantly doing this,

assessing short term, middle term, long

term, and reevaluating our goals.

Glenna Musante writes about the textile

and apparel industries and this past summer

won her third award in

three years for

textile science

feature writing.

Performance

wear, from yoga at-

tire to military issue,

is a primary focus area.

She can be reached at glenna@

musantecommunications.comor

www.glennamusante.com.

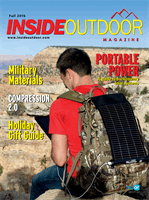

The Army Combat Pant (ACP) is a flame

resistant pant designed for use in rugged combat

environments. The ACP features a ruggedized,

anti-abrasion coated seat panel, stronger

twill fabric in the body of the pants and stretch

fabric at key stress points. The ACP has

integrated, removable hard-shell knee pads

with horizontal and vertical points of

adjustment built into the pants.

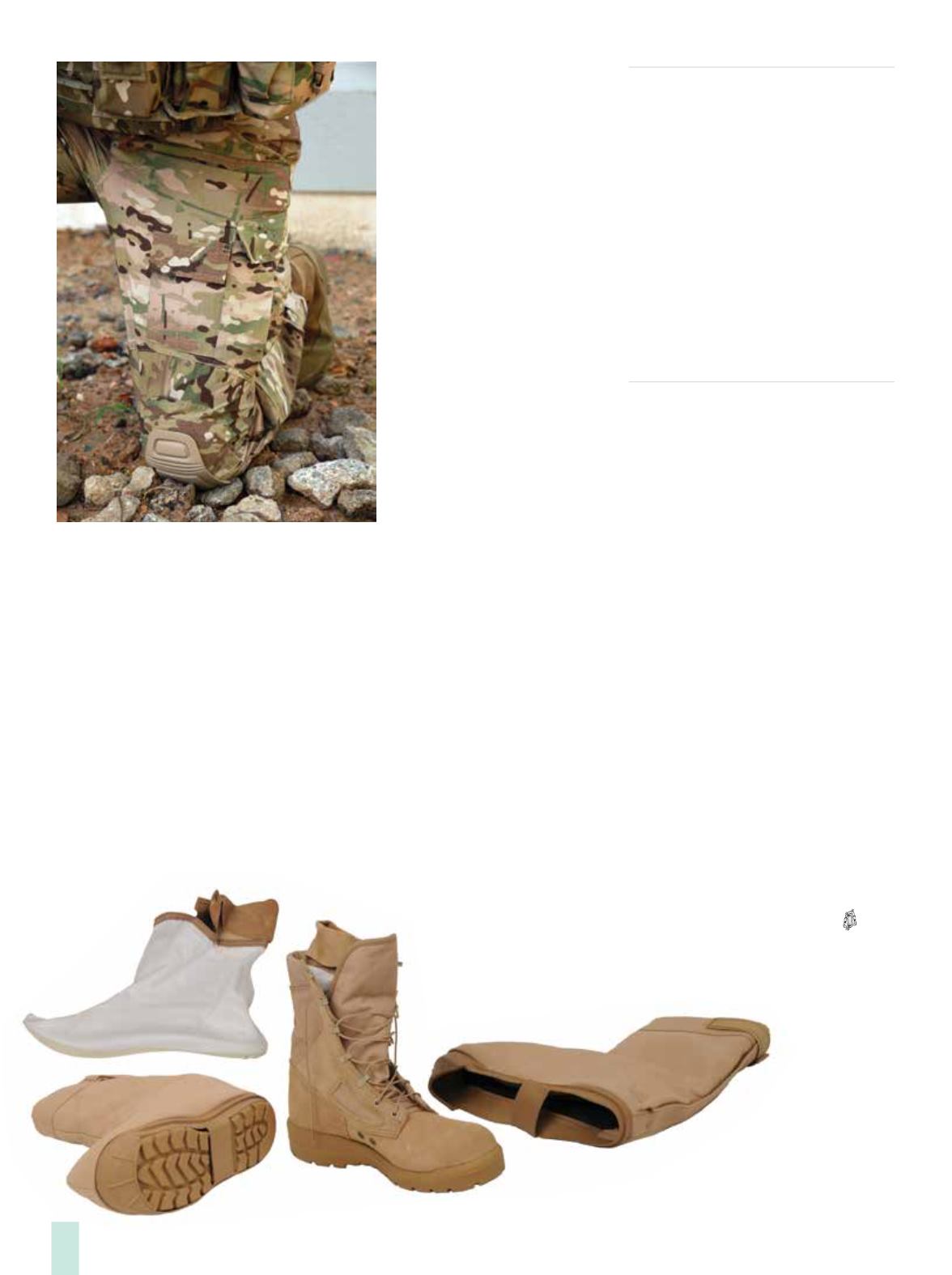

PEO Soldier Modular Boot System

“We haven’t selected

a new jungle fabric or

uniform. We are in the

development space for

the jungle uniform …

We’re looking for

lightweight materials

that are quick-drying,

breathable, provide

vector protection, no

melt no drip, and are

durable.” – Dr. Zheng

Inside

Outdoor

|

Fall

2015

30