“persistent” – it resists safely going away.

Its stick-to-itiveness and endemic cast

makes the associated problems formi-

dable. Yet its tenacious stability is the

reason why PFOA and its family of like

chemicals are so extremely useful.

The secret to the functionality of this

class of fluorocarbon compounds lies in

the strong chemical bond between the

fluorine atom (the fluorine in fluoro),

the carbon atom and fluorine’s unique

character. The resulting fluoro-carbon

bond is persistently stable in many

environments. Within this group, also

referred to as perfluorocarbons (PFC),

a class of industrial chemicals was cre-

ated. One of these compounds, perfluo-

rooctanoatic acid (PFOA), also known

by its contraction C8, is used as a build-

ing block in the production of fluo-

ropolymers. Another widely used PFC

is perfluorooctane sulfonate (PFOS),

a powerful surfactant whose range of

usefulness includes functioning like

detergents, emulsifiers, dispersants and

foaming agents. Collectively, this group

of PFCs includes C5, C6, C6 sulfonate,

C7 and homologs (longer chains of the

same base unit common to these par-

ticular PFCs) C9 through 12.

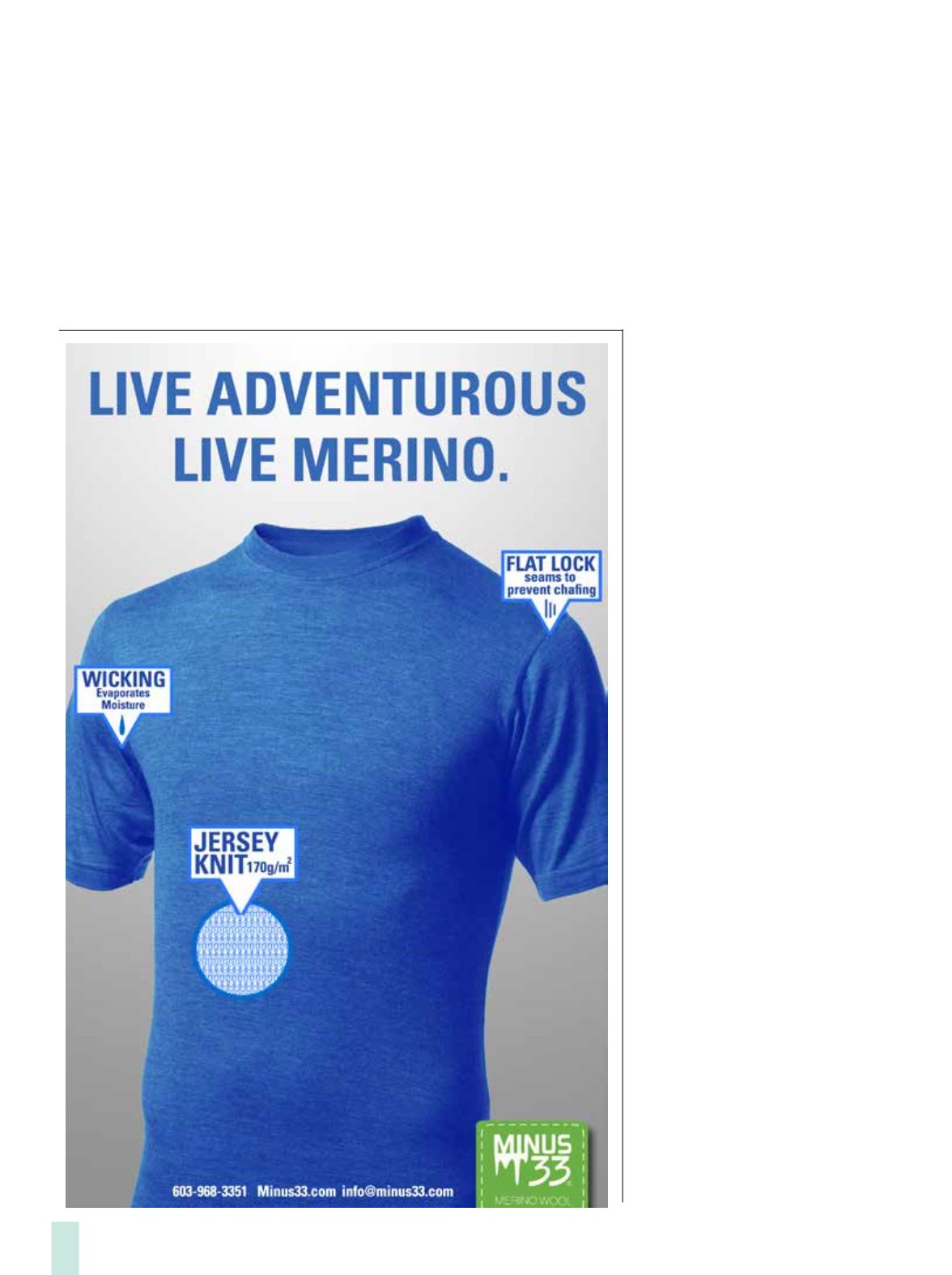

As it turns out, the outdoor recreation

industry has been using PFCs for almost

as long as they have been around. PFOS

is found within the many textiles used in

making apparel, tents, sleeping bags and

backpacks. PFOS helps keep outdoor

fabrics water resistant as durable water

repellents (DWR). 3M’s Scotchgard was

one of the best known PFOS-derived

DWRs, bringing stain and water repel-

lency to a wide range of consumer

products including furniture, curtains,

floor coverings and backpacking gear.

“Garments and equipment treated

with fluoro-technology also have a

longer useful life, therefore reducing

energy and water used to manufacture

replacements,” says the FlouroCouncil,

a gobal industry council for fluoro-tech-

nology. “They also require less frequent

laundering, lower wash temperature

and shorter drying time, further reduc-

ing use of water and energy.”

PFOA derivatives were exploited for

their low friction, non-stick, heat-re-

sistant properties particularly with the

invention of Teflon. Is there a household

in the late 1960s not taken up by the

space-aged miracle of non-stick frying

pans? The space age also saw the use

of Teflon in space suits and eventually

in other technology spin-offs such as

in the waterproof laminate membranes

Gore-Tex and eVENT.

For the outdoor retail industry, it is

pretty clear PFCs are pretty special, in-

deed, essential to the integrity of many

outdoor recreation products.

Globally, fluoro-technology materials

and products specific to the outdoor ap-

parel and equipment industry generate

a total of about $27 billion annually in

economic output, says to the Ameri-

can Chemistry Council. Their ubiquity

requires the replacement solutions or

options to be carefully vetted. Given that

it is 2015, will the pact made by the ma-

jor producers of PFOA reach the EPA’s

goal of eliminating them as set out in the

2010/15 Stewardship Program? How

will the new products balance perfor-

mance with environmental compliance?

According to Jessica Bowman,

executive director of the FluoroCouncil,

Atomic Backland Carbon Light

Inside

Outdoor

|

Spring

2015

26