For sporting goods retail-

ers tired of the space, cost and

messiness of using polystyrene

peanuts in shipping boxes

(recycled peanuts or not), the

new Fill-Air FLOW provides

an interesting and affordable

alternative. Replacing packing

peanuts for relative peanuts, the

$475 inflatable packaging sys-

tem makes protective air pillows

similar to those used by Amazon

and other large online dealers

affordable for the first time.

According to Sealed Air,

inventor of the original Bubble

Wrap and many other packag-

ing solutions sold worldwide, the

Fill-Air FLOW provides a space-

saving, cost-saving and environ-

mentally friendly alternative to

using polystyrene peanuts as

void-fill and cushioning in pack-

ing boxes, making protective air

pillows accessible for users with

low-volume shipping needs and

limited space in back rooms.

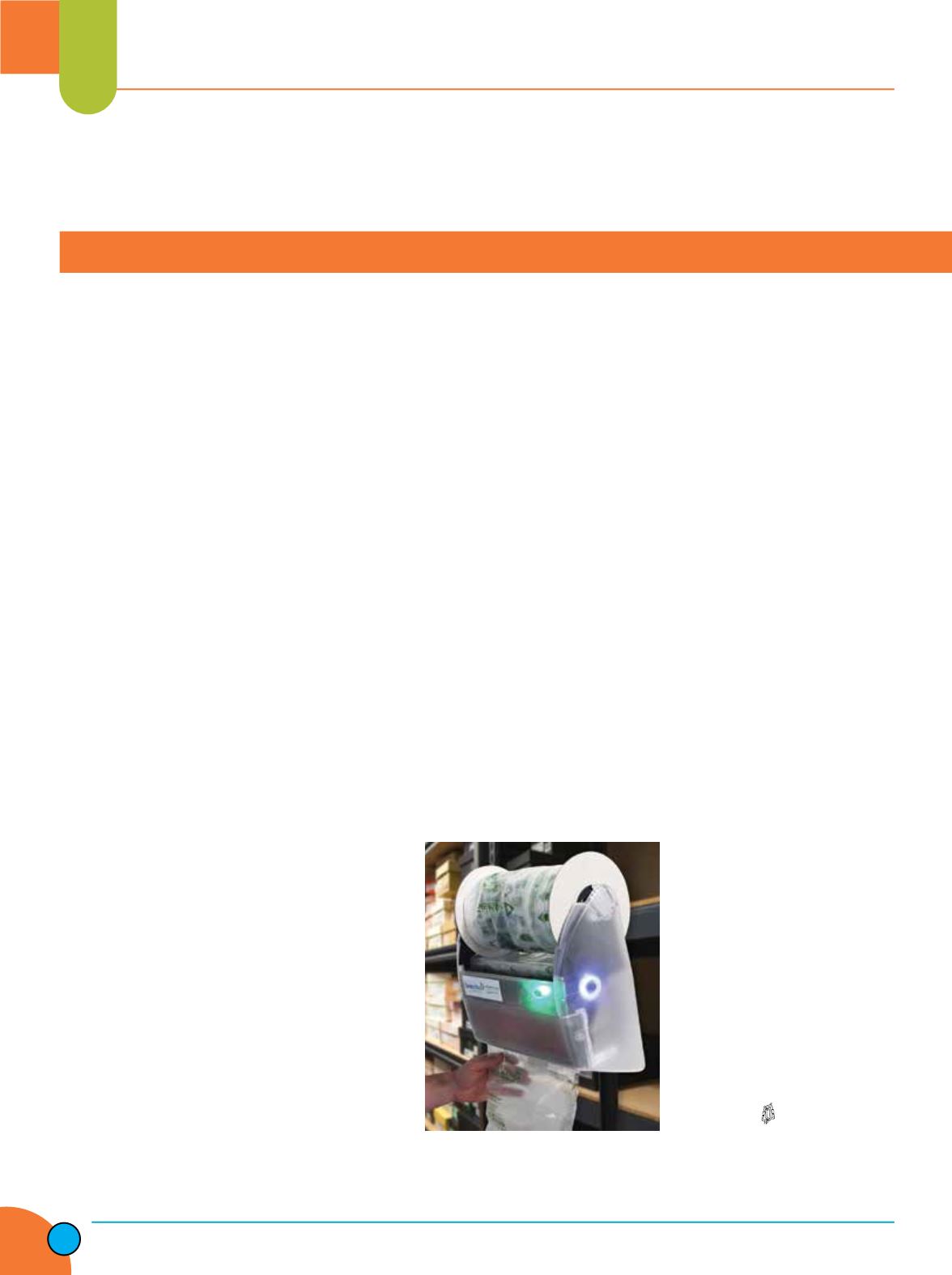

The inflation unit is mounted

to a wall or tabletop. A single

roll of ready-to-inflate plastic

bags frees up nearly 50 cubic

feet of storage space compared

to packing peanuts and also

costs less than the equivalent

peanut fill volume. The system

also offers better shipping pro-

tection, neater packaging for

customers and an eco-friendly

alternative to polystyrene, says

Millennium Packaging, which is

the exclusive U.S. distributor of

the Fill-Air FLOW.

The mounted device produces

11 high-fill or 20 low-fill inflated

plastic bags per minute. Both

the machine’s 13″ x 14″ x 8″

footprint and the inflation speed

are suited to environments with

moderate shipping volumes such

as retail shipping service cen-

ters, retail stores, e-tailers, light

industry, company mail rooms,

marketing and advertising agen-

cies, printers, law firms, artists’

studios, art festivals and more,

said the company.

Each FLOW roll contains 500

10″ x 8″ ready-to-fill perforated

bags in a spool not much larger

than a roll of paper towels. A

single roll produces fill volume

equivalent to more than three-

and-a-half 14-cubic-foot bags of

packing peanuts, freeing up near-

ly 50 cubic feet of storage space

per roll. At $50 per 500-bag roll,

inflatable packaging with Fill-Air

FLOW costs roughly $1 per cubic

foot of fill compared to $1.30 to

$1.90 per cubic foot for retail-

priced packing peanuts. The refill

rolls also are available exclusively

from Millennium Packaging.

Operation of the Fill-Air

FLOW is as simple as swiping

a hand over a sensor located

on the side of the unit for each

bag desired, or holding a hand

over the sensor for three sec-

onds to inflate 100 bags at a

time. High-fill or low-fill can

also be selected with the touch

of a button. An optional photo

sensor attachment for use with

a continuous flow setting will

stop production when it detects

a set number of inflated bags

and resume it when the bags

are removed, making it possible

to have bags ready for immedi-

ate use without inflating the

whole roll at one time.

“Major retailers like Ama-

zon have been using inflatable

packaging technology for years,

but until now the price point

has prevented smaller organiza-

tions from realizing the ben-

efits,” said John Tyrrell, presi-

dent of Millennium Packaging.

“At less than $500, Sealed Air’s

Fill-Air FLOW enables compa-

nies of any size to send peanuts

packing forever.”

“The Fill-Air FLOW has

changed everything. It’s more

efficient, less material, less

packing time, and the space sav-

ings is unbelievable,” said Helen

Ann Lally of Your Neighborhood

Office, a business help center

and errand service in New York’s

Greenwich Village that was an

early tester. “When we took the

peanut hopper out of here, I was

able to put in drop ceilings that

gave me another floor of stor-

age space.”

For more information or to

order the Fill-Air FLOW, visit

www.parcelpkg.com.“At less than

$500, Sealed

Air’s Fill-Air

FLOW enables

companies

of any size

to send peanuts

packing forever.”

Affordable Packaging System Replaces

Annoying Peanuts

FLOOR

SPACE

By

Martin

Vilaboy

The new Fill-Air FLOW system

makes protective air pillows

affordable even for users with low-

volume shipping needs.

Inside

Outdoor

|

Fall

2016

44