In a move to no doubt reinforce

the May acquisition, DSM introduced

The Dyneema Project just ahead of

the Outdoor Retailer Summer Mar-

ket. The Dyneema Project’s mission

statement reads not unlike the an-

nouncement of a newborn by a proud

parent crossed with the awarding of a

Nobel Prize.

“Beginning in 2015, Dyneema will

be made more widely available to the

apparel market through a carefully

curated innovations program – The

Dyneema Project – undertaken in close

collaboration with selected brands and

mills,” said the company. “This project

honors the most cutting-edge brands

and state-of-the-art mills – those push-

ing the envelope of design and vision.

The Dyneema Project is dedicated to

the trailblazers, game changers and

innovators in apparel.”

As part of its “by invitation only”

commitment to expanding its techno-

logical reach, DSM is providing support

to designated trailblazers. It is accom-

plished through an active consultancy

in the way Intel supports computer

companies in the appropriate use of

its processors. It involves research and

development, sourcing mills and manu-

facturers and manufacturing support.

DSM calls it “Tailor made consultancy.”

Recipients of The Dyneema Project

honor include Levi Strauss and Co.,

adidas, Hyperlite Mountain Gear, Gi-

ant and Saint (Australian motorcycle

apparel), among other cutting-edge

fashion brands.

Of those, Levi Strauss and Co.,

already known for its sustainable de-

velopment work, has had encourag-

ing results with the use of Dyneema

in its denim. The implications for

outdoor apparel manufacturers are

many and on different levels. On

the all-important performance-driven

side, adding 5 percent to 10 percent

Dyneema in denim increases tensile

strength and tear resistance up to

100 percent over standard denim.

Abrasion resistance is improved up

to 200 percent. In comparison, high

tenacity nylon requires double the

amount of yarn yet remains 5 times

less tear resistant.

Esthetically, the hand, look and feel

of the denim remains unchanged – the

classic reasons why we love our jeans.

Environmentally, fewer raw materials

required to accomplish greater ends

means a better product and a smaller

carbon footprint. A stronger more du-

rable pair of jeans also suggests having

to replace them less frequently, again,

reducing the carbon footprint. DSM’s

Neil Bell, and former Global Fabric In-

novation Manager at Levi Straus, con-

curs. “We also don’t need to use more

cotton and materials to make more

(jeans),” he said. “We see the innova-

tion of Dyneema jeans in the fact that

they last two-and-a-half times longer

than a normal pair of jeans. By doing

this, people don’t need to buy a second

pair of jeans.”

Unquestionably, Dyneema has lots

to offer outdoor apparel in terms of

performance and the environment. The

hurdles seem to be similar to any new

technology. Product development has

to be at the point where the learning

curve matches what manufacturers

expect with a new technology. As a

premium solution, acknowledging the

value proposition is key until the econ-

omy of scale can address a larger part

of the market.

Finally, a Life Cycle Assessment

(LCA) must be commissioned to ensure

Dyneema’s environmental profile is in

line with the outdoor industry’s think-

ing going forward. If most of the above

conditions are met, and The Dyneema

Project’s seeds take root, it will not be

long before we see more lighter weight,

much stronger and smarter apparel

coming our way.

Anthracite-colored Dyneema Cubic Technology Fabric

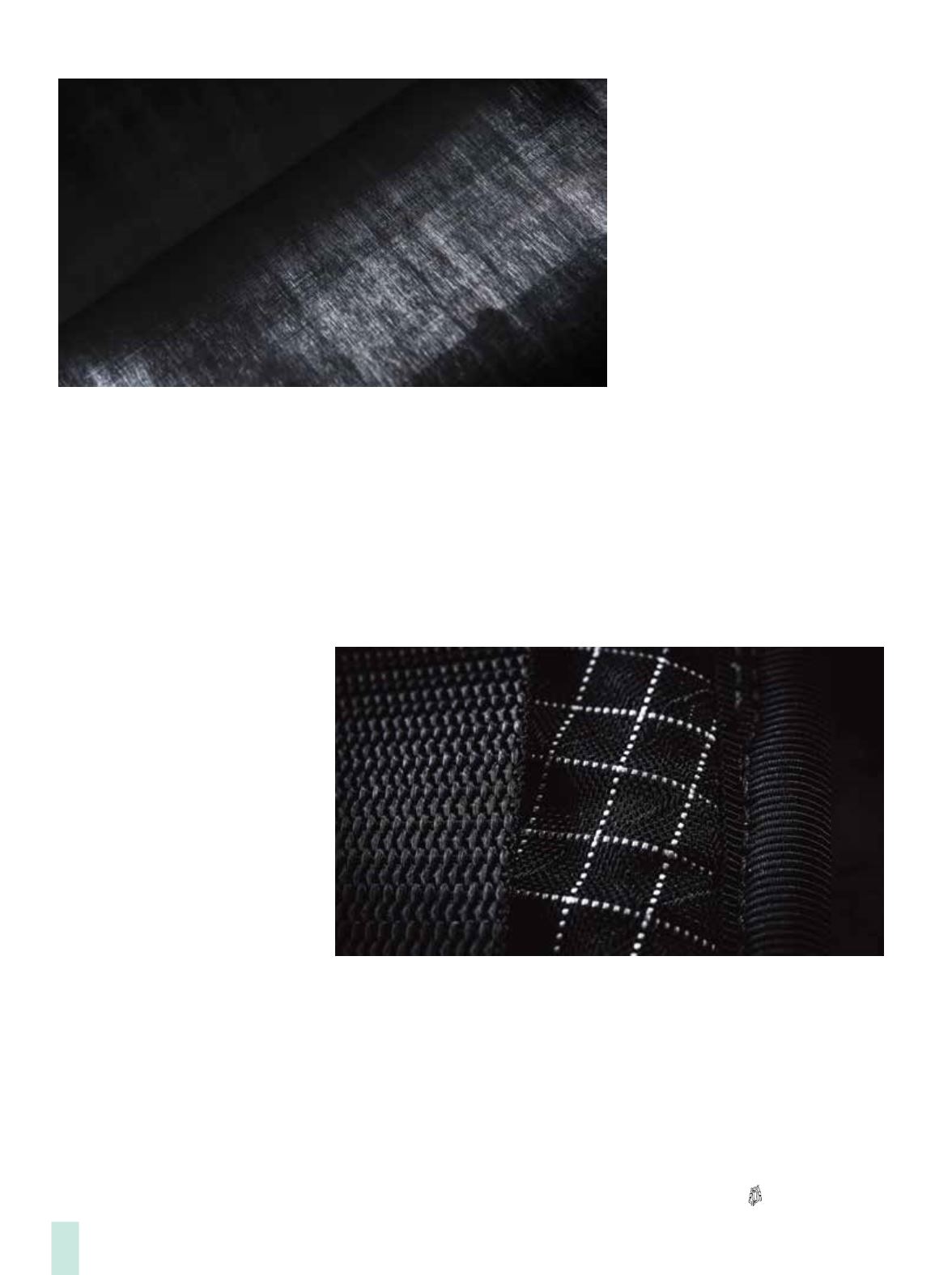

Swatches of state-of-the-art materials developed by Dyneema Project with

collaboration partners.

Inside

Outdoor

|

Winter

2016

34