and fuel cell varieties in addition to the very mature electro-

mechanical and photovoltaic stalwarts. Today’s consumer

is confronted with all these choices, in all manners of scale.

However, of the above technologies, photovoltaic (PV) or

solar power remains the dominate

technology within the personal

portable category.

PVs have a lot of features,

making them very attractive to

any front or back country trav-

eler. They are extremely depend-

able – there are no moving parts

to break, and they offer virtually

failsafe operation. PV technology

is robust, which is why NASA has been using it in space

since the 1950s. It is simple to operate; just plug-and-play.

PV is becoming more eco-friendly both pre- and post-man-

ufacturing. Recent advances in PV technology might soon

be ushering in new carbon-based cells, making them easier

and much cheaper to build. Finally, today’s PV offerings are

broadly available at retail.

Given there are so many choices in PV products, con-

sumers (and sales staffers) may wonder what makes them

fundamentally the same but different. To answer that, this

basic primer on PV function will attempt to clarify the

philosophical differences between technologies. This is fol-

lowed by a hypothetical trekking scenario for which seven

photovoltaic manufactures of outdoor power options were

asked to offer solutions.

The photovoltaic effect was first noted by a young French

physicist, Alexandre-Edmond Becquerel, in 1839. Yet it took

more than 120 years before efficiency breakthroughs helped

propel its commercialization (ie. 1960s). To efficiently gener-

ate electric current in materials exposed to sunlight, certain

physical properties of chemical compounds are required.

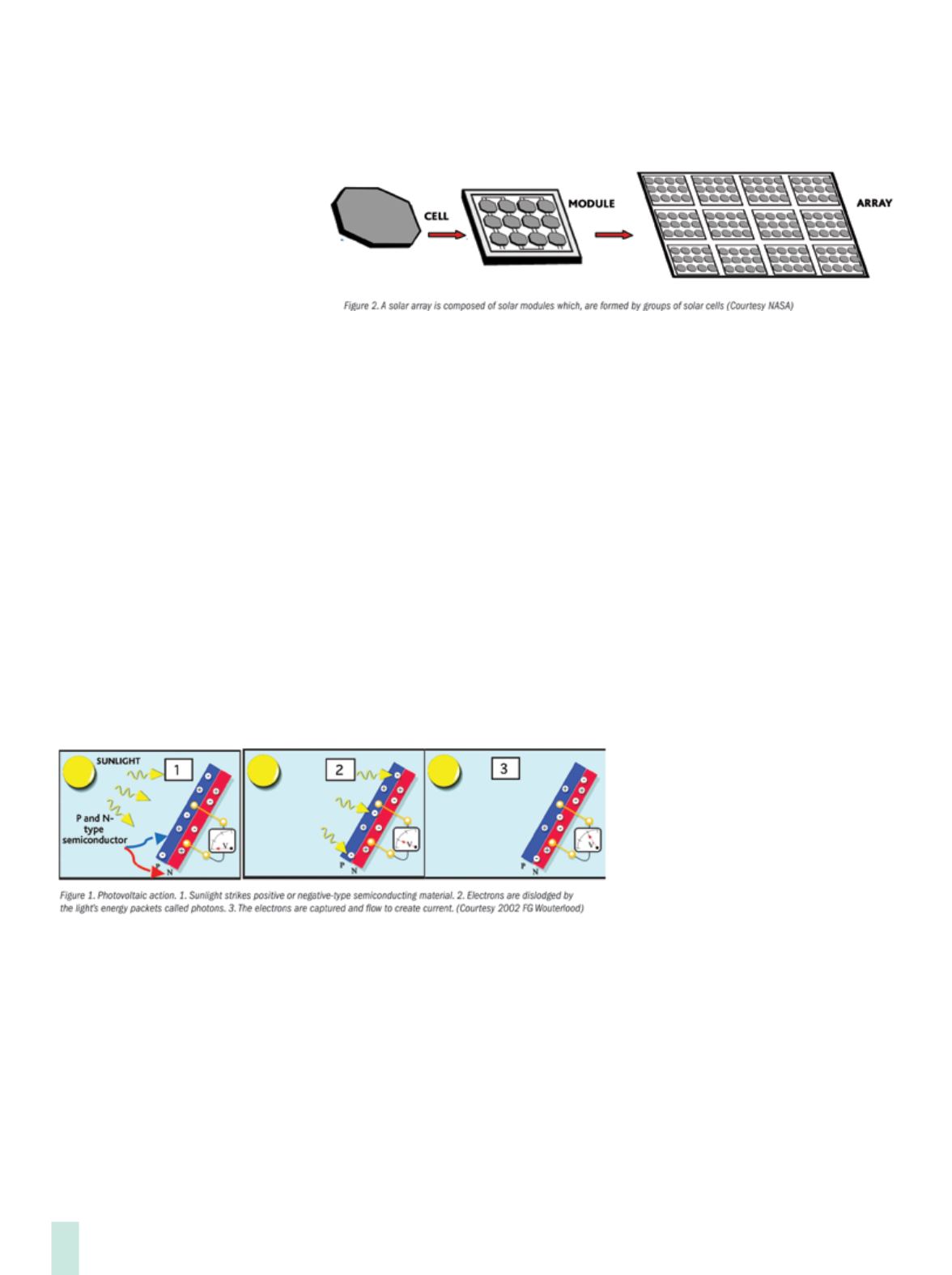

Silicon-based semiconductors, the foundation of most

microelectronic circuitry, are the principle materials used in

solar cells. Semiconductors are compounds whose tweakable

electrical conductivity dictates the extent and direction of the

positive to negative or negative to positive current flow. Lay-

ers of semiconducting material, or wafers, are constructed in

such a way as to create a positive and negative electrical field

on opposite sides of the wafer and are joined together to form

a circuit. When sunlight hits this semiconductor, electrons are

freed up and captured by aforementioned electrical fields,

inducing current flow or electricity (Figure 1).

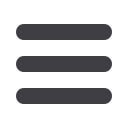

The smallest PV units are called cells. They are ganged

together to make larger modules and even larger arrays,

powering structures such as the International Space Station or

a typical North American home (Figure 2).

Variations in chemistries, wafer design and overall con-

struction affect the efficiency or the ability to convert sunlight

to electrical current. Monocrystalline, polycrystalline and

amorphous silicon are the most common cell materials. In

general, monocrystalline is high-purity silicon with the great-

est efficiency. Continued advances in the less-expensive and

lower-efficiency polycrystalline technology are rapidly closing

the efficiency gap. Amorphous silicon, used exclusively in thin

film PV, has the lowest efficiency but, in many respects, the

greatest versatility. It is bendable, thin, cheaper to manufacture

and the most environmentally friendly. This brings up another

categorical difference: form factor.

When it comes to form factors, there are mainly two:

ridged monocrystalline and polycrystalline modules and

flexible thin film modules. The end user has to determine, of

the two forms, what works best for them. Typically, ridged

modules have slightly higher efficiencies but are heavier

and bulkier. Flexible modules can be integrated into tent

walls or backpack panels and rolled-up for easy storage.

Another key difference in design is how cells are inter-

nally connected. If cells are connected similar to links in a

chain, it is referred to as series or a series circuit. Conse-

quently, if one cell is damaged or fails,

just as if a link in a chain disappears,

the whole chain fails and no longer

works. Parallel or parallel circuit is

when the cells have some level of inter-

connectivity. If one cell is compromised,

the current has alternative paths it can

follow to continue the flow of electric-

ity. Parallel circuitry is slightly heavier

and internally more complicated,

thus more costly to build.

Finally, all power-generating modules require batteries to

store their generated charge. Unless there is no need for power

during periods of diminished light or nightfall, consider

recommending a storage cell. There also are integrated panel/

battery systems or component kits available from manufactur-

ers, optimized to best utilize their special features.

What follows are product submissions to supply power

for a hypothetical trip. The trip scenario is a party of two to

four people with two to four smartphones and one tablet or

action video camera. Battery storage capacity is shown in

milliampere-hour (mAh). For comparison, an iPhone 6 battery

is purported to be around 1800 mAh. A Samsung Galaxy S6

advertises 2550 mAh. Prices are MSRP.

Inside

Outdoor

|

Fall

2015

16